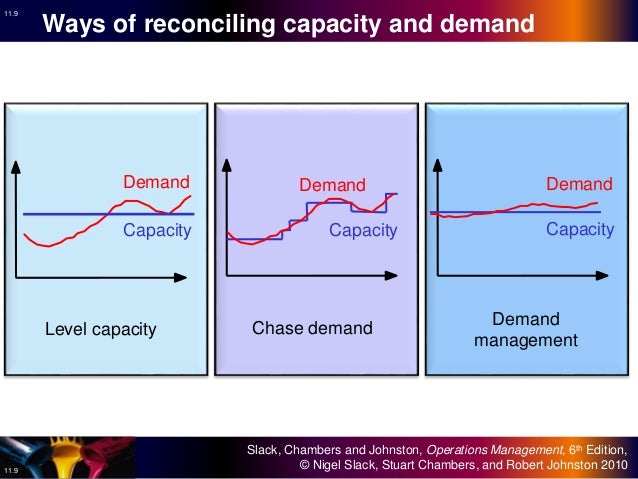

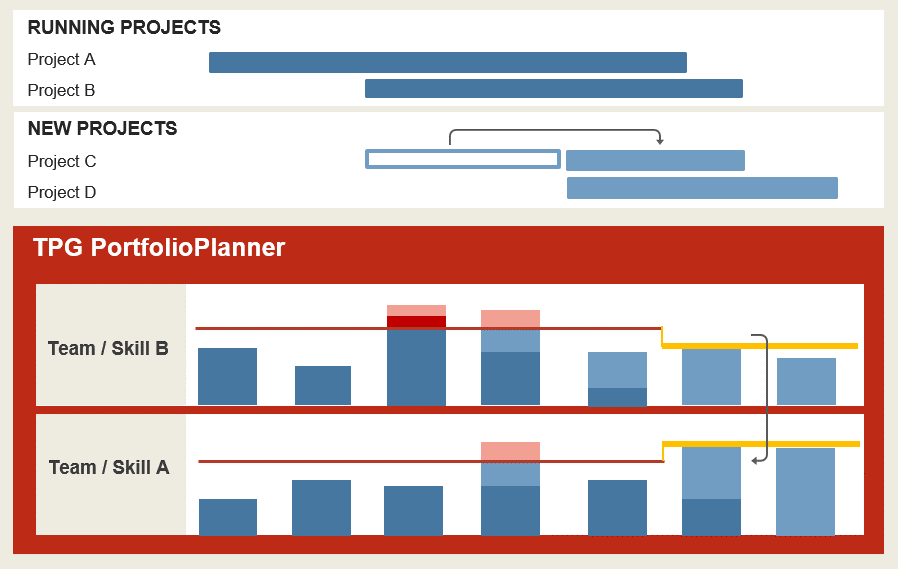

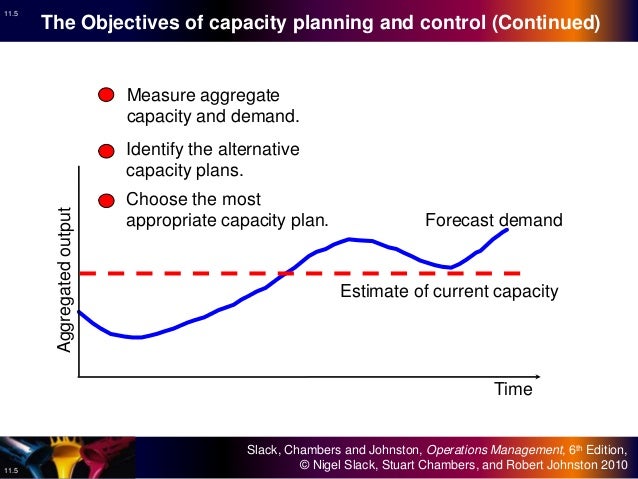

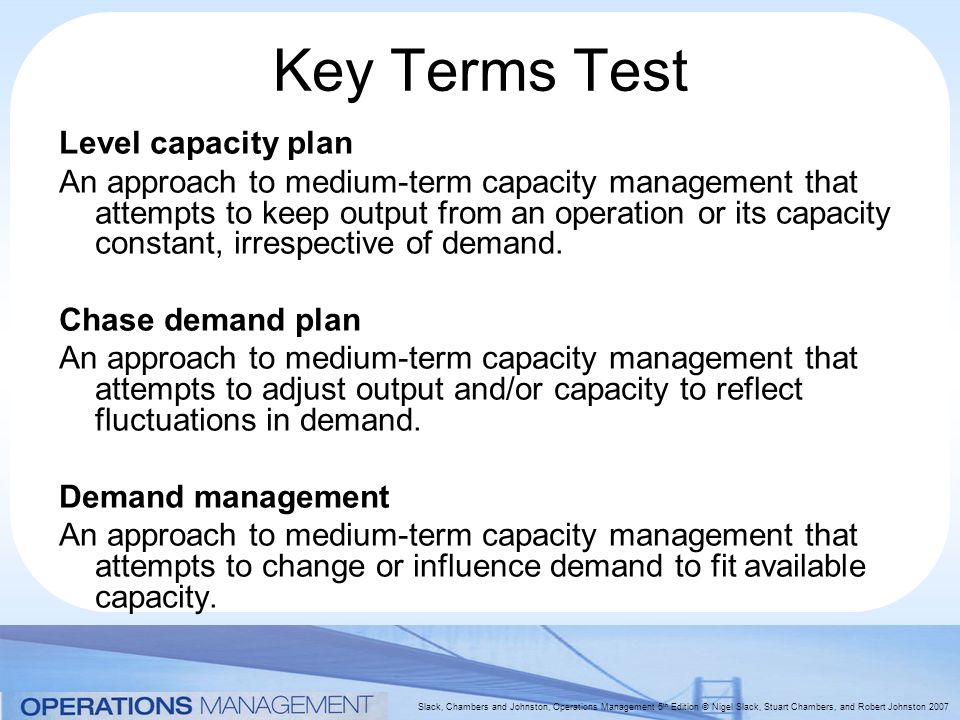

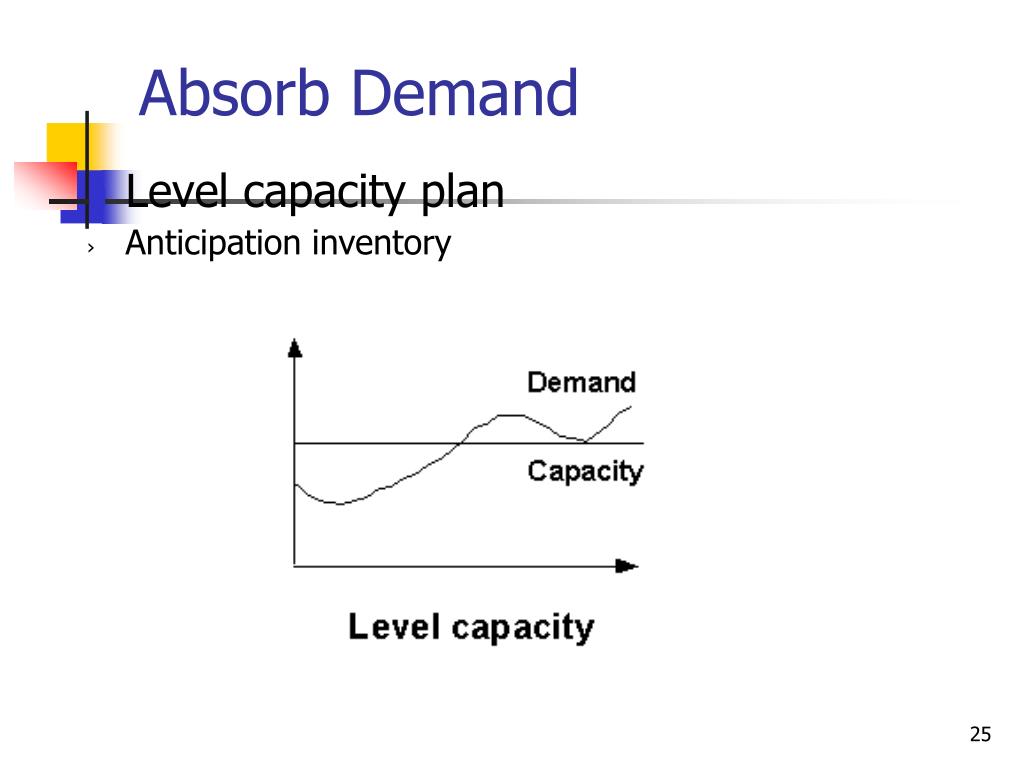

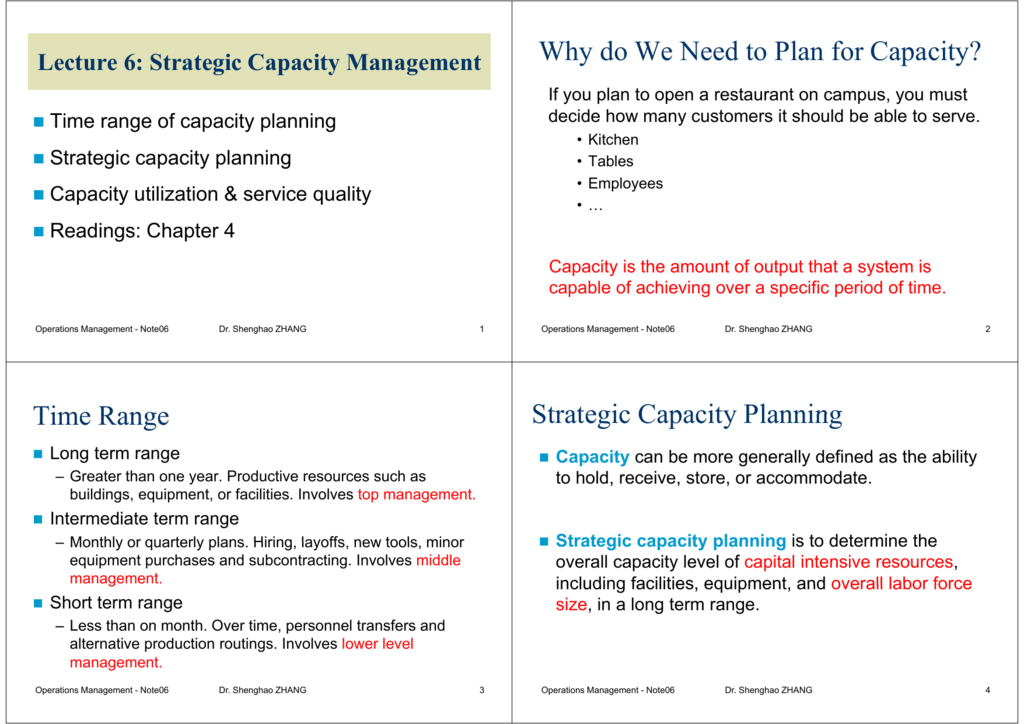

The alternative capacity plans level capacity plan – ignore the fluctuations and keep activity levels constant chase demand plan – adjust capacity to reflect the fluctuations in demand Demand management – attempt to change demand to fit capacity availability Level capacity planThe processing capacity is set to a uniform level throughout the planning period1) Themes This is the first level of your strategic plan template and it's your chance to spell out what your organization plans to focus its attention on this year Themes, often called areas of focus, are like the table of contents in a textbook When you need to quickly access information, you scan the table of contents, zero in and Begin with project level or phase level estimates – don't try to capture resource utilization at the task level It sounds great and is the nirvana of capacity planning, but don't do it Less granular data can still be very useful for answering the two questions at

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Level capacity plan

Level capacity plan-A period's planned quantity of output is equal to that period's expected demand Level capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demandThe objective of capacity management (ie, planning and control of capacity) is to match the level of operations to the level of demand Capacity planning in Production and Operation Management Capacity planning is to be carried out keeping in mind future growth and expansion plans, market trends, sales forecasting, etc It is a simple task

Level Capacity Plan Level Capacity Plan The Inventory Size Is Varied Keeping The Operation Management

The level capacity strategy, the focus is on the process where product output remains at a somewhat fixed level and increases/decreases in demand are satisfied through strategic decisions of utilizing inventory (maintain buffer stock), outsourcing and backorders In comparison to level capacity strategy is adjusting capacity to follow Selecting a capacity alternative most suited to achieving strategic mission 17 THREE STEPS OF CAPACITY PLANNING 18 Determine Service Level Requirements 19 The first step on the capacity planning process is to categorize the work done by systems and to quantify users' expectation for how the work gets down Define workloads 21Capacity is often measured in hours available to be worked by employees And in this context, "planning" is the act of scheduling employee hours against a fixed or expected amount of work Example A company has 10 employees Each employee works 40

With American Rescue Plan funds, USDA will provide $100 million to reduce the financial burden of overtime inspection fees for small and very small poultry, meat and egg processing plants, which provide farmers with local alternatives and greater capacity to process livestock Leveling the Playing Field for Independent Family Farmers and RanchersChecklist Capacity Plan Definition The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business demand, and options with cost estimates to deliver the agreed service level targets Download Our Capacity Planning Tool – Version We have a new capacity planning tool for you It takes in sales order data, calculates total demand and production load and then compares that to available capacity You can add your own data, and use this to predict the production capacity that is required and available to meet customer demand

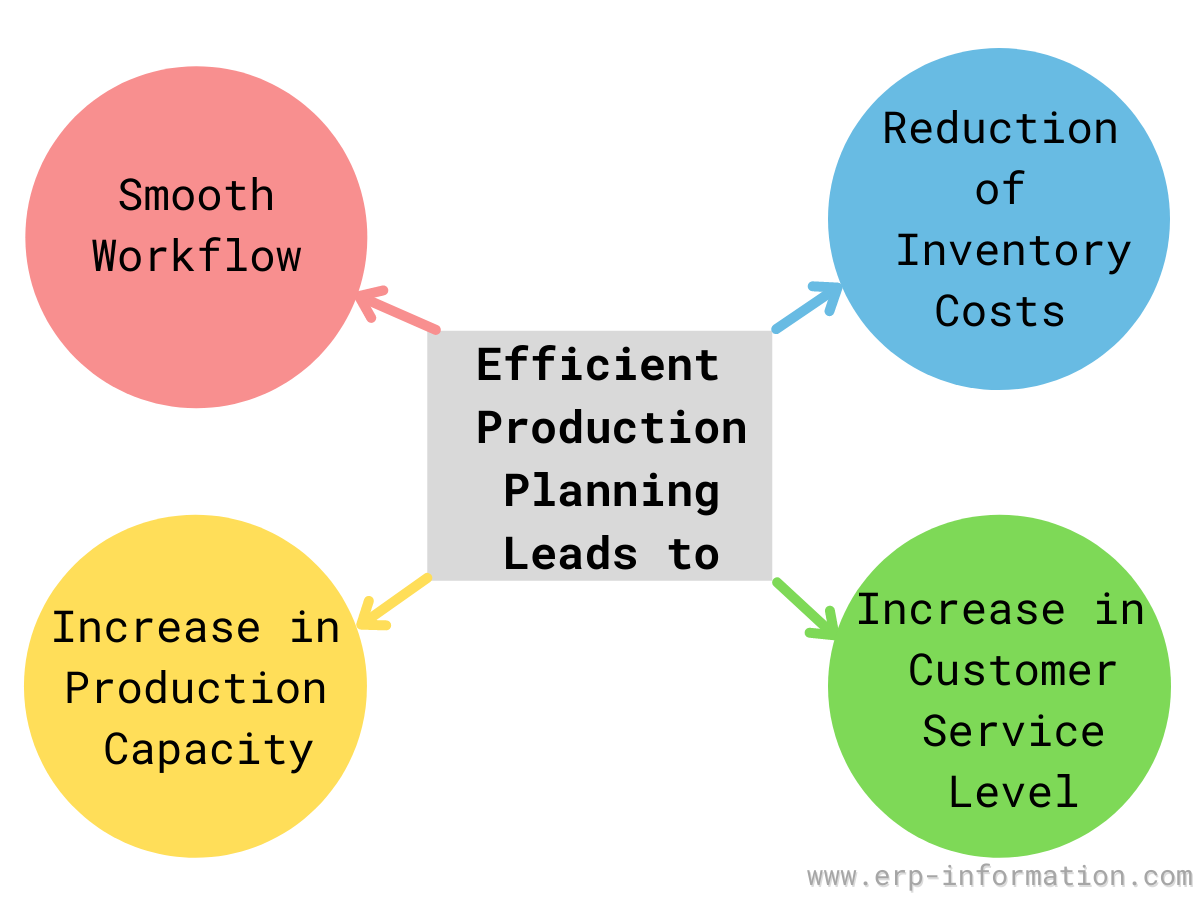

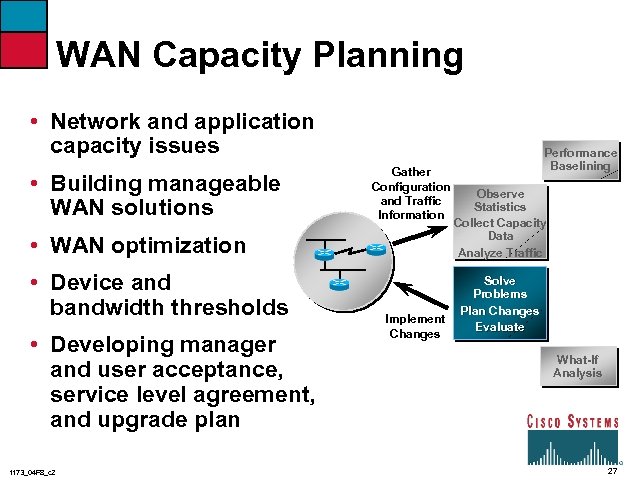

Capacity Planning used in conjunction with an ERP system can improve the accuracy of planning and help control costs as well as plan for future expansion and growth However, because each company is different, there are things to consider when using capacity planning in manufacturing Data Accuracy – Any software platform is only as accurate1 Collaborate and plan with a variety of community, civic, governmental and private organizations 2 Be familiar with the County's AllHazards Response Plan and the health and medical component presented in Annex G of the plan, which is developed by hospital, local public health, community clinics, mental health resources, and EMS 3The capacity of the business needs to be checked versus the production plan in order to ensure an achievable plan If there is not enough capacity, you may have to run an extra shift, use overtime or subcontract work In the shortterm when the Master Production Schedule is generated, capacity planning needs to be used to balance the workload

What Is Capacity Planning An Introduction Clarizen Success

5 Steps To Create A Tech Support Capacity Plan The Operations Blog

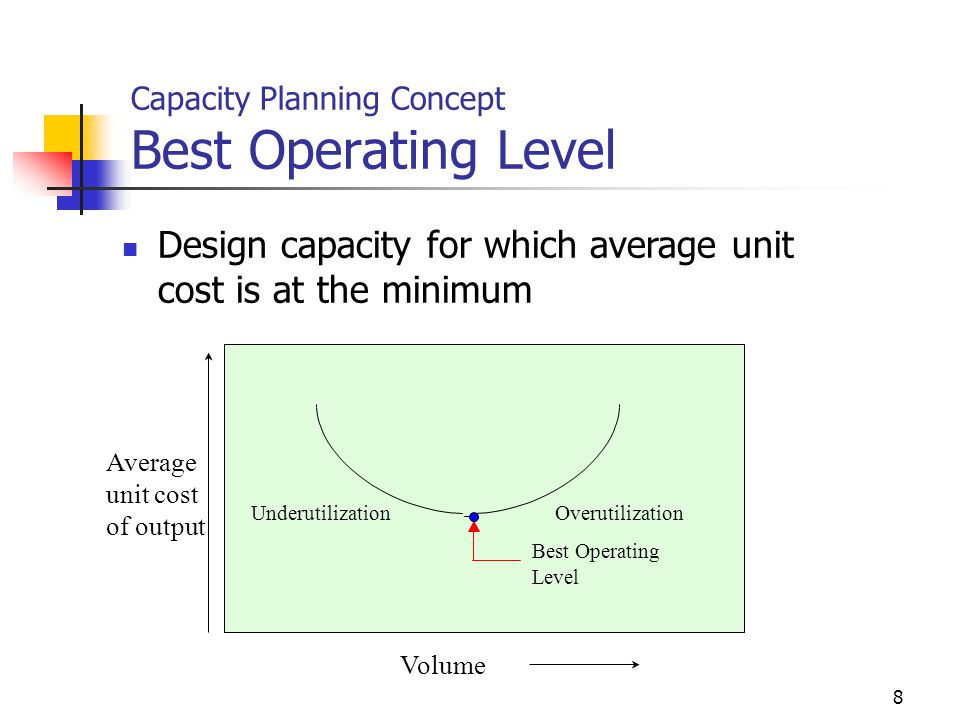

The Maharashtra government's fivelevel plan to unlock the state, based on weekly positivity rate and occupancy of oxygen beds in districts, came into effect from MondayAn approach to aggregate planning that attempts to match supply and output with fluctuating demand Depending on the product or service involved, the approach can incur costs by the ineffective use of capacity at periods of low demand, by the need to recruit or lay off staff, by learningcurve effects, and by a possible loss of quality The advantages include low storageCapacity is outsourcing, in which suppliers absorb the risk of demand uncertainty The best operating level for a facility is the percent of capacity utilization that minimizes average unit cost Rarely is the best operating level at 100 percent of capacityat higher levels of utilization, productivity slows and things start to go wrong

Sales And Operations Planning Aggregate Planning Production Planning Operations Planning How To Meet Effectively And Efficiently Forecasted Requirements Ppt Video Online Download

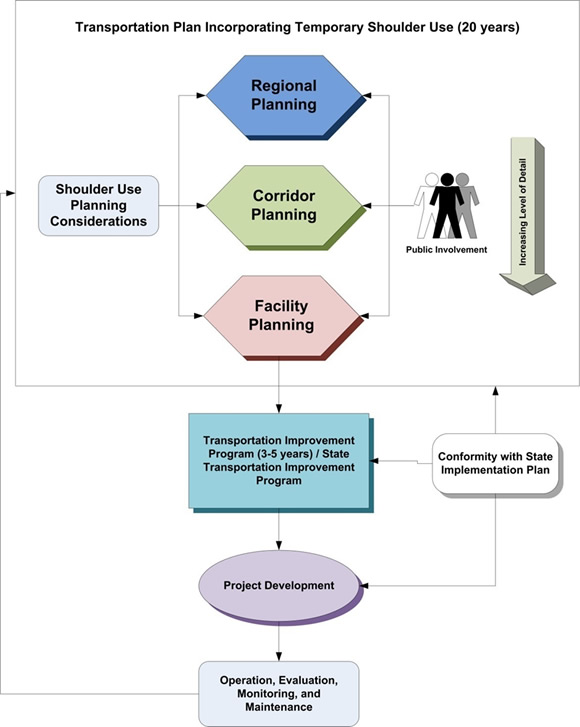

Efficient Use Of Highway Capacity Summary Chapter 1 Background Fhwa Operations

At the operations level, disaggregated capacity planning breaks down the aggregate plan into operational plans with shorter timeframes The disaggregated plan results in a master schedule that can then be operationalized into shorter time buckets of months, weeks, days, shifts, etc"The level capacity plan satisfies high demand from existing stocks When demand goes below capacity, overproduction is stored as inventory in anticipation of higher demand in later months The disadvantage of this approach is that this tends to build in high stock levels and hence high levels of working capital are required What is a level capacity plan?

Infrastructure Capacity Planning Tools Market By Technology Advancement And Business Outlook 21 26 The Courier

What Is Capacity Planning Examples Types Optimoroute

And the capacity level for each period that maximizes the firm's (supply chain's) profit over the planning horizon – Specify the planning horizon (typically 3 to 18 months) – Specify the duration of each period (typically 1 month for longer horizons) – Specify key information required to develop an aggregate planIn other words, Manager A is tied to the "chase demand" strategy, and his counterpart, Manager B in the adjacent office, is locked into the "level capacity" strategy However, each desires toLevel capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demand This may lead to stockpiling or holding of inventory in high quantity, when there is a decrease in the demand level

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Entries For Thursday 25 October 07 Sergio S Blog

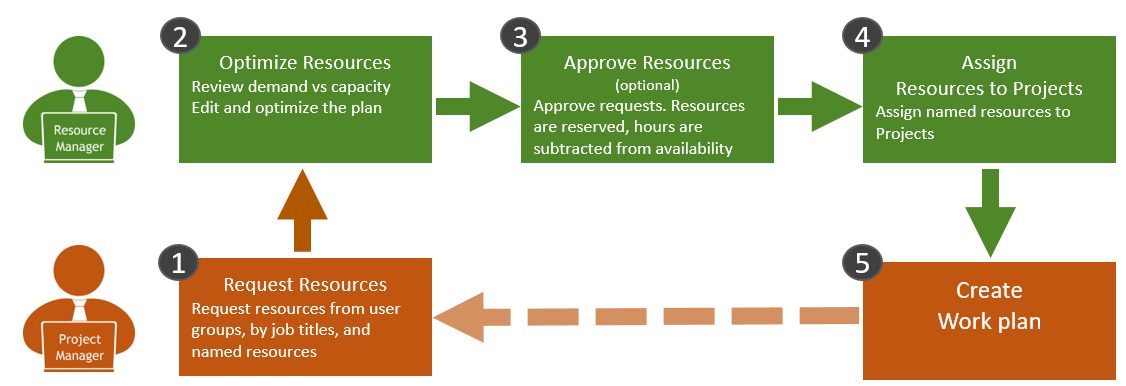

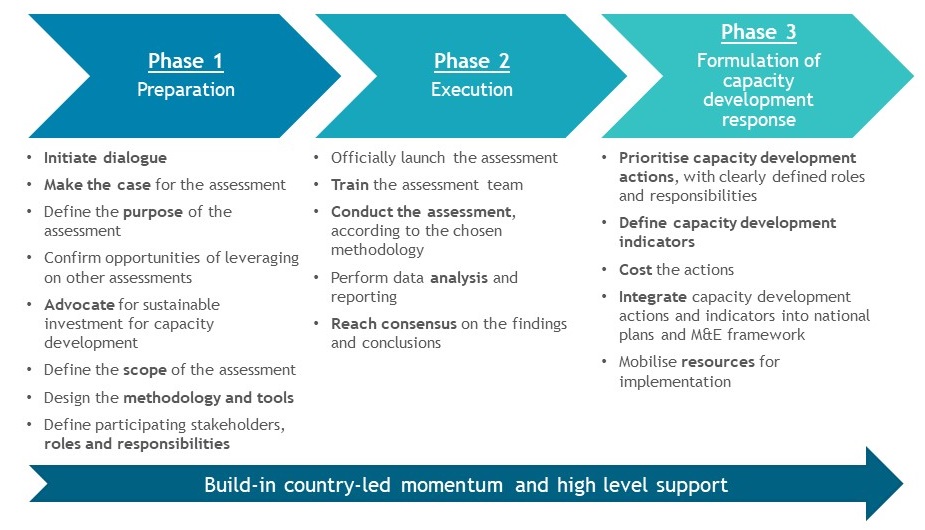

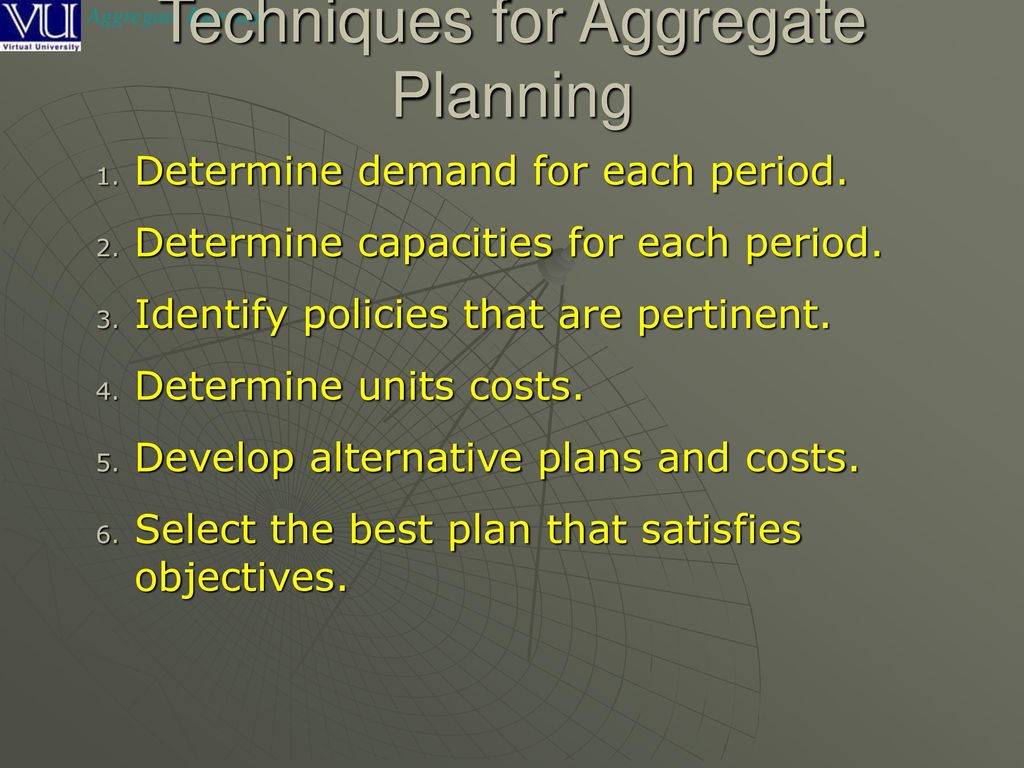

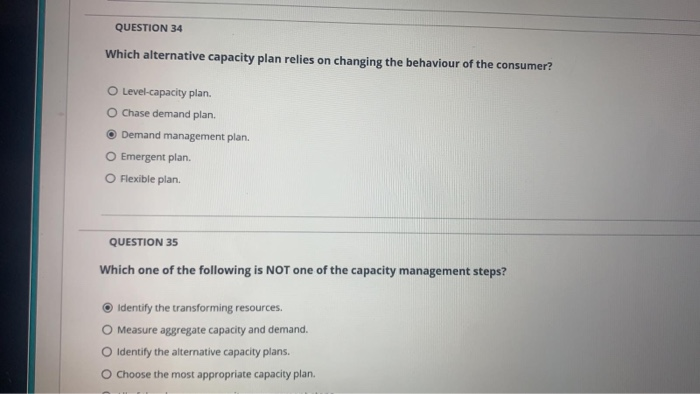

Survey participants were asked what level best describes the Capacity Planning or Resource Management Maturity Level for their organization The following are descriptions that were provided in the survey Level 1 is the lowest level of maturity to Level 5, the highest levelIdentify the transforming resources Measure aggregate capacity and demand Identify the alternative capacity plans O Choose the most appropriate capacity plan Capacity planning is a process that balances the available hours of teams against what the project needs Capacity, in this case, is the most work that can be done over a

Mastering Resource Capacity Planning And Demand For Optimum Project Performance Katalyst

Strategic Capacity Planning Aggregate Planning Ppt Video Online Download

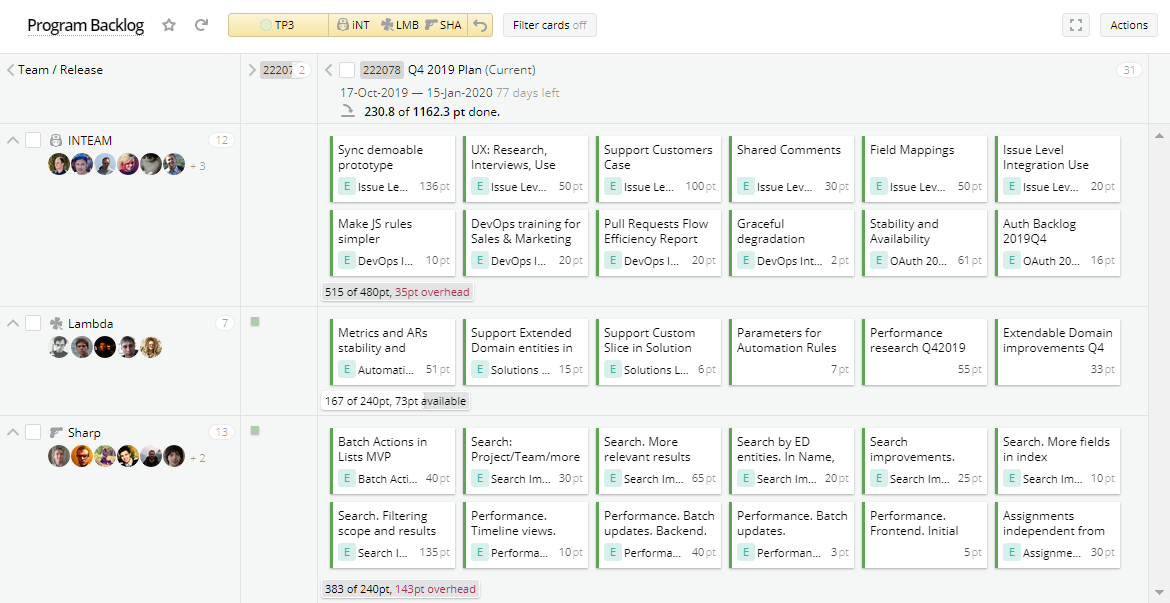

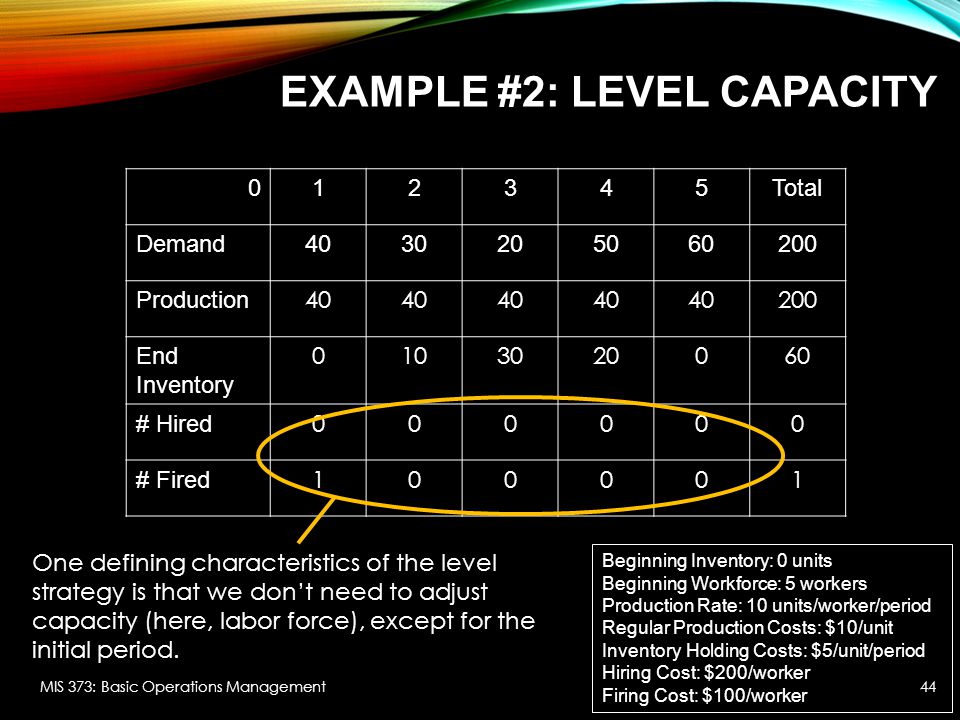

Capacity Planning refers to the arrangement in which organizations or teams match employees together with the needs of a project Capacity is the optimum level of work that can be done within an established period Usually, it is measured in the quantity of work that isLevel Capacity Plan Definition An approach to mediumterm capacity management that attempts to keep output from an operation or its capacity constant, irrespective of demand Operations Management by Nigel Slack, Alistair BrandonJones, Robert Johnston Level Capacity PlanIn plans, capacity is directly associated with teams, where capacity is measured as a whole for the team To display team capacity in your plan Make sure you've already associated the teams in your plan with the corresponding issue sources Only then can team capacity

Sales And Operations Planning Aggregate Planning Production Planning

Www Kronos Com Resource Download

The Surge Plan is intended to be a highlevel response plan, identifying the experts and specialized resources that exist within the county/region, demonstrating how hospitals will create surge capacity, describing how health care assets and resources will be deployed, how care will be coordinated across the continuum of care, and outlining theStrategic capacity planning is essential as it helps the organization in meeting the future requirements of the organization Planning ensures that operating cost are maintained at a minimum possible level without affecting the quality It ensures the organization remain competitive and can achieve the longterm growth planLevel Capacity Plan The inventory size is varied keeping the workforce size and utilization of work constant The number of workers (working size) is kept constant throughout the time period under consideration During months of low demand the excess units required over the units produced are taken from the inventory

Level Capacity Plan Level Capacity Plan The Inventory Size Is Varied Keeping The Operation Management

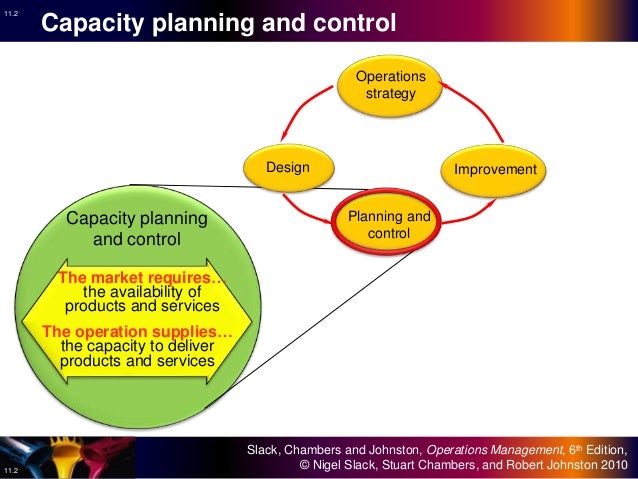

Capacity Planning And Control Ppt Download

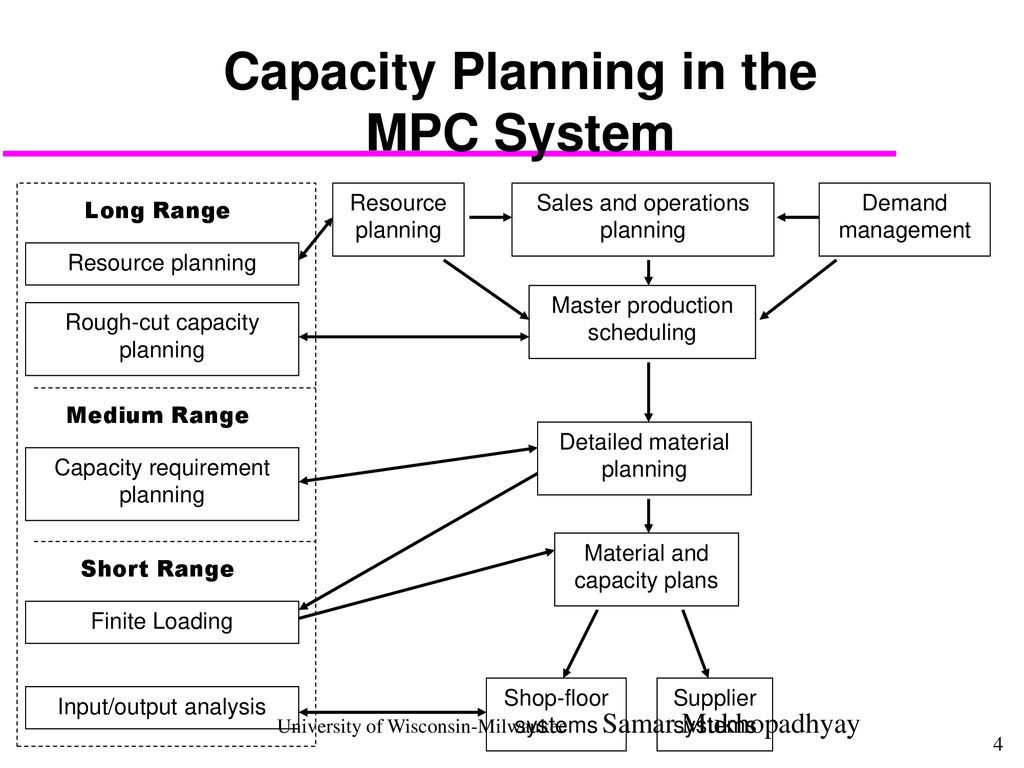

Capacity requirement planning forms part of the operational stage of the planning process and works in conjunction with a manufacturing requirement planning (MRP) system A detailed capacity requirement plan provides an operational level overview for the production cell and assists the operations manager with identifying all of the elements 3 Examples of Production Capacity John Spacey, Production capacity is the volume of products or services that can be delivered by the operational resources of an organization Resources include factors such as land, labor, facilities, infrastructure and machines The following are illustrative examples of production capacity Capacity planning manufacturing is a method of calculating the realistic capacity (how much you can produce) of your production lines to keep up with forecasted demand Your capacity planning manufacturing can be set to achieve short or longterm goals

Metron Capacity Management Capacity Management Guided Practitioner Satnav Capacity Plan 16 Of 17

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

The first is called level scheduling, where you try and maintain a steady workforce with a steady schedule The second is the chase strategy, where you maintain a level workforce and increase your workforce as demand increases This may mean using overtime or hiring temporary employees The type of laborscheduling you wish to incorporate canA level capacity plan Measurement has revealed the following information on an operations system Design capacity was 84 units per hour, planned losses were 12 units per hour, and actual output was 65 units per hour What were the utilisation and efficiency of the operation respectively? Here is a very basic example of what a high level capacity plan looks like Model Tips Create excel tables that allow flexibility and automation For example, set up a formula so when any of the influencers change up or down, the capacity plan updates on its own (This allows you to leverage "what if" scenarios)

11 Capacity Planning And Control Operations Management

Checklist Capacity Plan It Process Wiki

Levelcapacity plan Chase demand plan Demand management plan Emergent plan Flexible plan QUESTION 35 Which one of the following is NOT one of the capacity management steps? Capacity requirements planning (CRP) is the process of discerning a firm's available production capacity and whether it can meet its production goals The CRP method first assesses the company's Choose the sprint you want to plan The system lists only those sprints that have been selected for the current team focus If you don't see the sprints you want listed, then see Define iteration (sprint) paths Set capacity for the team and team members From the Capacity page, you can add team members, enter the team time off, and set

Sap Heuristics

26 Resource Capacity Plan Template Resource Planning Template Human Capacity Project Business Plan Template Free Business Letter Template Action Plan Template

Capacity planning is the practice of planning/determining production capacity and workforce needs to make sure your supply chain is equipped to meet demand Capacity planning lets businesses know how and when to scale, identify bottlenecks, create better design capacity, and mitigate risk, within a planned period of timeFrom Wikipedia, the free encyclopedia Capacity planning is the process of determining the production capacity needed by an organization to meet changing demands for its products In the context of capacity planning, design capacity is the maximum amount of work that an organization is capable of completing in a given periodDevelop production plan 2 Check implications for inventory/backlog plan 3 If necessary, adjust production plan 4 Capacity Level of labor skill required Low High Job discretion Low High Compensation rate Low High Training required per employee Low High Labor turnover High Low

11 Capacity Planning And Control Operations Management

What Is Production Planning Erp Module And Its Features

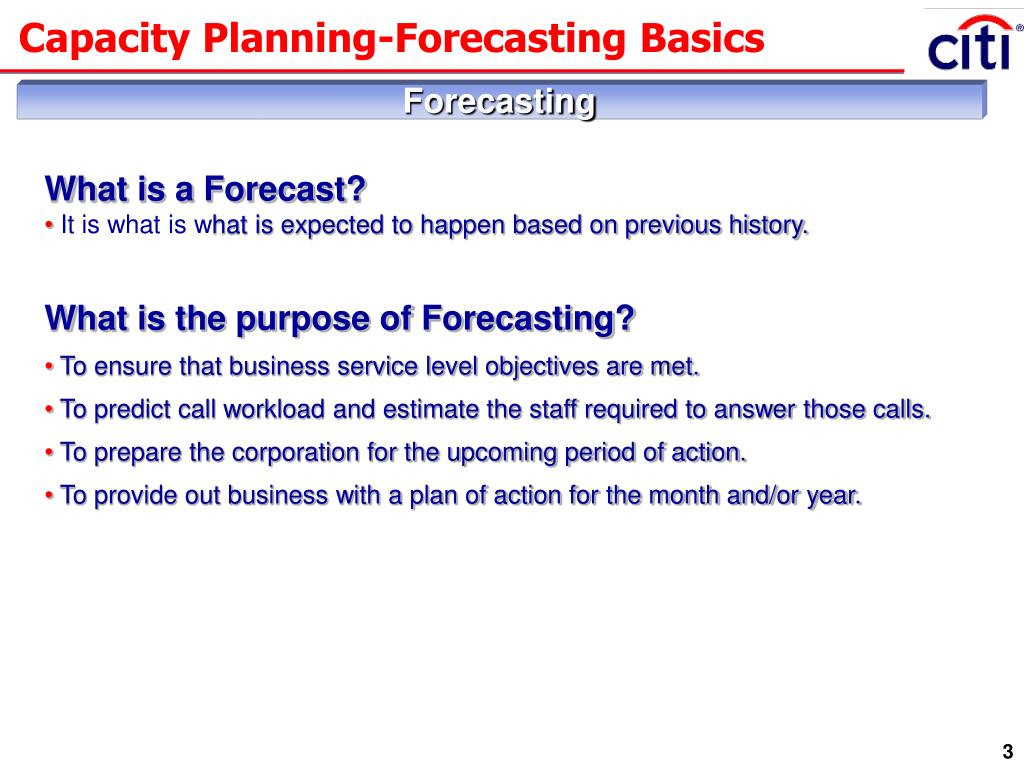

The capacity plan is the important and major output of capacity planning Based on the service level targets and requirements, IT service provider has to meet the targets agreed with the customer or business Capacity planning strategy involves the process used to determine the resources manufacturers need to meet the demand for their products or services The level of capacity directly relates to the amount of output in the form of goods and services manufacturers can produce to satisfy customer demandTo teacher learning to focus less on implementing specific programs and more on building lasting capacity for instructional improvement This white paper from the Literacy Organizational Capacity Initiative (LOCI) analyzes the professional learning systems of four high capacity districts and distills a framework of 11 common factors

Capacity Planning And Control Chapter 11 What Is

Pdf An Optimisation Approach For Capacity Planning Modelling Insights And Empirical Findings From A Tactical Perspective Semantic Scholar

What Is Capacity Planning Examples Types Optimoroute

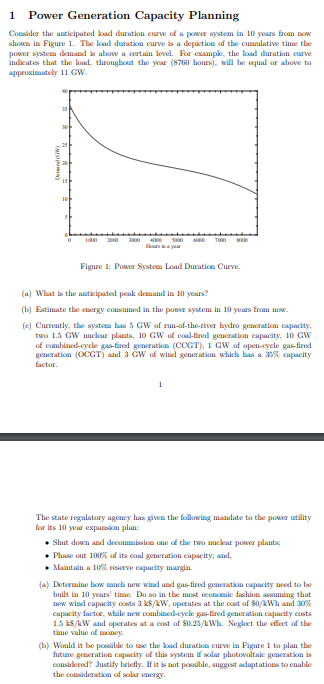

1 Power Generation Capacity Planning Consider The Chegg Com

The Future Of Strategic Operations Management

Capacity Management Objectives Roles Concepts Mitsm

Capacity Planning And Control

Capacity Planning Everything You Need To Know Opensense Labs

Capacity Planning And Control

11 Capacity Planning And Control Operations Management

5 Capacity Planning For Products And Services Mc

Chapter 3 Strategic Capacity Management Ppt Video Online Download

Capacity Planning And Control Ppt Video Online Download

Essay Utwente Nl 1 Puspasari Ma Mb Pdf

A Critical Insight To Successful Supply Chain Planning

Nipn Capacity Development Plan Nipn

Chapter 7 Capacity Planning And Management Ppt Download

Naas Playbook Capacity Planning Telecom Infra Project

Figure 2 From Hierarchical Capacity Planning With Reconfigurable Kits In Global Semiconductor Assembly And Test Manufacturing Semantic Scholar

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Capacity Planning And Predicting Growth For Vista Capacity

Advanced Planning And Scheduling Solutions Boost Productivity Applied Materials

Capacity Requirement Planning

Parry Operations Management Managing Capacity Youtube

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

Value To The Business Capacity Management Is Responsible For Ensuring That It Resources Are Planned And Scheduled To Provide A Consistent Level Of Service That Is Matched To The

Capacity Planning Meaning Classification And Its Goals

What Is Capacity Planning Examples Types Optimoroute

Feature Based Capacity Planning Targetprocess Enterprise Agility Solution

Peoplesoft 8 4 Production Planning Peoplebook

1

Ppt Capacity Planning Powerpoint Presentation Free Download Id

Operations Management Capacity Demand Planning And Control Week Planning Is What Activities Should Take Place In The Operation When They Should Take Place What Studocu

What Is Capacity Planning Examples Types Optimoroute

Elements Of Who Capacity Building Plan 36 Download Table

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Aggregate Planning Mps Capacity Planning Strategic Management Inventory

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

Myclass Dau Edu cswebdav Xid 4 5

Concept Of The Optimisation Model For Technology And Capacity Planning Download Scientific Diagram

Capacity After Deciding What Products Services Should Be Offered And How They Should Be Made Management Must Plan The Capacity Of Its Processes Capacity Ppt Download

23 Best Capacity Planning Ideas Capacity Planning Capacity How To Plan

3

Q Tbn And9gcqytvm28phg Flc1jbxscbyoduapoqtpbknwdc60pk3a2805i I Usqp Cau

Can Capacity Planning Technology Help Plan Labor Budget

Ppt Operations Management Powerpoint Presentation Free Download Id

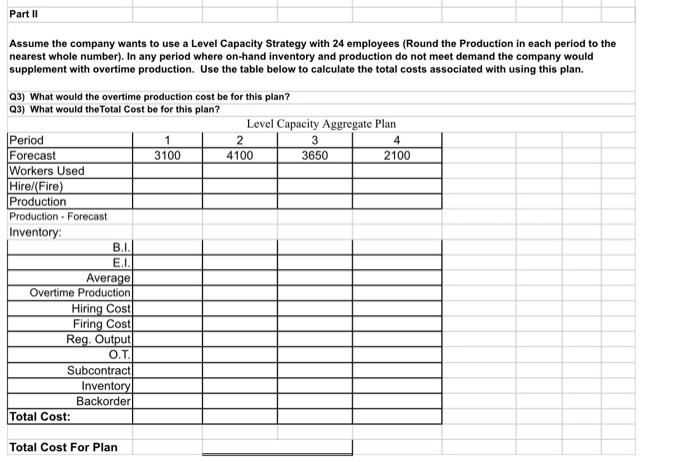

Solved Part Ii Assume The Company Wants To Use A Level Ca Chegg Com

Aggregate Capacity Planning Pdf Free Download

Capacity Management Process Pink Elephant United Kingdom

Capacity Planning Everything You Need To Know Opensense Labs

Operational Uncertainty Mbaid My Study

Reorder Point And Working Capital Plan Projections Safety Stock Point Capacity Planning

Module 5 Capacity Planning Inventory Operations Management

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

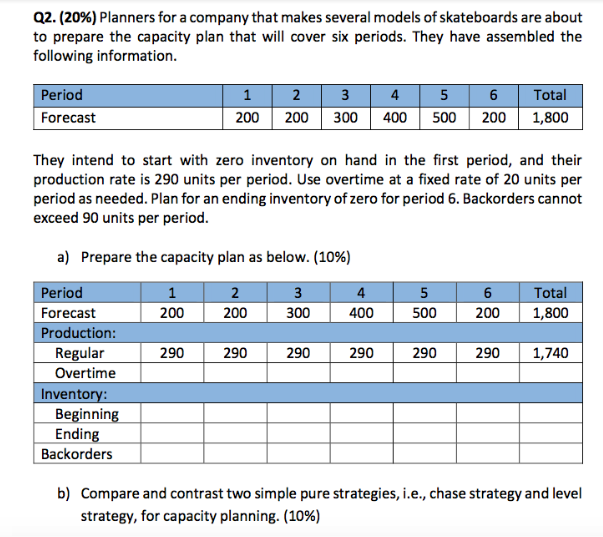

Q2 Planners For A Company That Makes Several Chegg Com

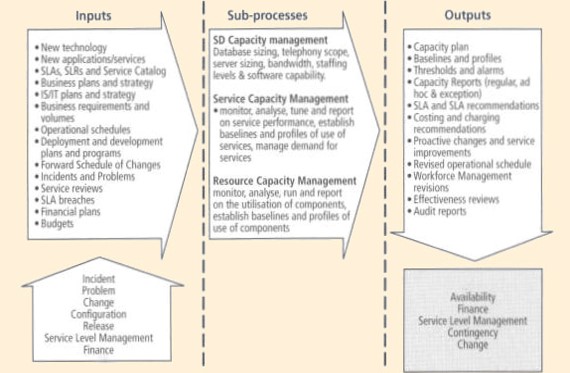

Inputs And Outputs To Aggregate Production Planning Capacity

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Capacity Requirement Planning

Www Sap Com Docs Download 06 943efecf 9f7d 0010 87a3 C30de2ffd8ff Pdf

Operations Management Lesson 8 Flashcards Quizlet

Parry Operations Management Managing Capacity Youtube

Level Capacity Plan Approach Ppt Powerpoint Presentation Summary Cpb Powerpoint Shapes Powerpoint Slide Deck Template Presentation Visual Aids Slide Ppt

Mba638 Files Wordpress Com 17 01 Om L5 Capacity Management Pdf

Capacity Planning And Control

23 Best Capacity Planning Ideas Capacity Planning Capacity How To Plan

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

3

Time Range Strategic Capacity Planning

Capacity Planning For Enterprise Networks An Overview Of

Level Capacity Plan Approach Ppt Powerpoint Presentation Summary Cpb Powerpoint Shapes Powerpoint Slide Deck Template Presentation Visual Aids Slide Ppt

Itil Service Management Itil Management Project Management Templates Project Management Task Management

Pdf An Approach To Capacity Planning Of Distribution Warehouses For X Firm Semantic Scholar

Manufacturings Objectives The Goal Of Manufacturing Is To

Solved Question 34 Which Alternative Capacity Plan Relies Chegg Com

How To Create Use A Capacity Plan Review Of Optometric Business

Uninote Ecommerce S3 Eu West 2 Amazonaws Com Capacity management Pdf

1 Capacity Planning Framework Download Scientific Diagram

Capacity Planning Apics Forum

Study Of Manufacturing System Capacity Planning Control Steps In Capacity Planning Measuring Demand Capacity Yield Management

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

Operations Management Daniel S Blog

0 件のコメント:

コメントを投稿